Eclipse Furnnox

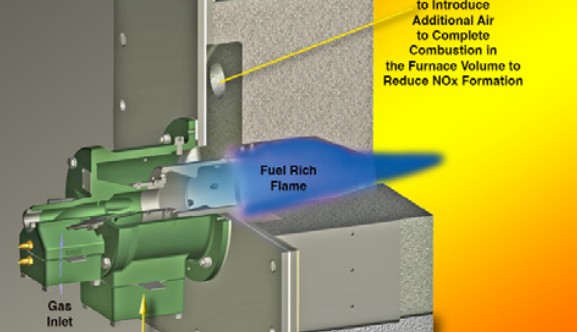

The Eclipse Furnnox burner is a direct fired furnace burner designed for continuous high-temperature processes—such as in the steel industry—offering exceptionally low emissions. In most high-temperature applications, Furnnox burners can achieve NOx emissions below 30 ppm at 3% O₂. To ensure optimal efficiency, the burner maintains the correct air-to-fuel ratio across its full operating range. It is available in two configurations: a standard version for combustion air preheated up to 150°C, and a high-temperature version with an insulated housing, capable of handling preheated air up to 600°C. The Furnnox supports direct ignition throughout its full ignition and operating range without requiring a pilot light. Typical applications include electroplating furnaces, forging furnaces, and heat treatment furnaces. To achieve low NOx emissions, the combustion chamber must operate with less than 5% O₂. Reducing excess air and lowering oxygen levels in the chamber further improves NOx performance.

Features and Benefits:

Documentation:

Features and Benefits:

- NOx emissions < 30ppm (at 3% O2) in most high temperature oven applications

- Power from 66 kW to 530 kW

- Turndown up to 10:1

- Max. process temperature: 1540°C

- Preheated air up to 150°C in standard version

- Pre-heated air up to 600°C with specially insulated housing

- Fuel: natural gas, propane, butane

Documentation:

Didn't find what you were looking for?

The brands we distribute sometimes sell thousands of products. Only the most common products and components are offered on our website.

If you are looking for a specific piece that you cannot immediately find here, please do not hesitate to contact us. We will be happy to help you!